15.1 Safety, health and environmental regulations/legislation specific for the mixture EU Legislation

Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/EC and repealing Council Regulation (EEC) No 793193 and Commission Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC, including amendments. Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 on classification, labelling and packaging of substances and mixtures, amending and repealing Directives 67/548/EEC and 1999/45/EC, and amending Regulation (EC) No 1907/2006 with amendments. Employment restrictions: Observe employment restrictions for young people, for child bearing mothers/ nursing and for women of child-bearing age.

15.2 Chemical Safety Assessment

Exposure scenarios are not required for this mixture because it is not classified as dangerous according to Directive 67/548/EEC and assessed to be not PBT/ vPvB. No risk management measures as defined by REACH have been identified.

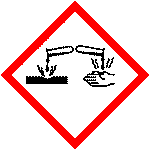

GHSO8

GHSO8  GHSO5

GHSO5